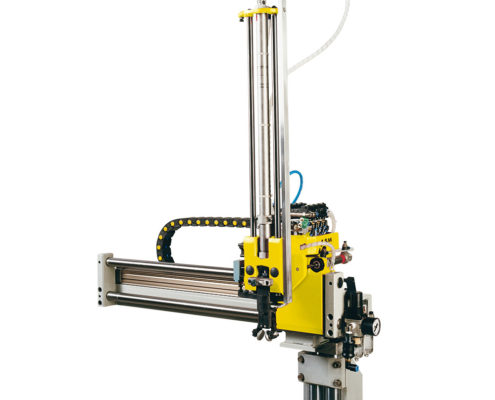

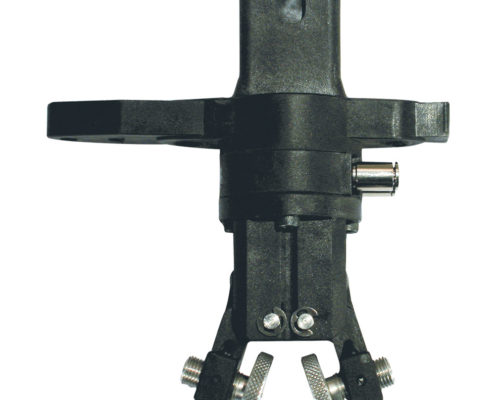

THE MN SERIES WAS DESIGNED TO HANDLE SPRUES OR COMPONENTS IN THE PLASTIC INJECTION FIELD, FOR INJECTION MOULDING MACHINES FROM APPROX. 40 TO 200 TONS. THIS MACHINE SERIES COMES IN TWO VERSIONS THAT DIFFER BY VIRTUE OF ELECTRONIC OR PNEUMATIC INTERNAL LOGIC. THESE MACHINES ARE DISTINGUISHED BY THEIR RELIABILITY, VERSATILITY AND SIMPLICITY OF USE. THE MN SERIES PNEUMATIC VERSION PERFORMS A FIXED CYCLE, WHILE THE ELECTRONIC VERSION, WITH ITS CONTROL BOX, CAN CONTROL GRIPPERS, SPECIAL PICK-UP EQUIPMENT, 0-90° WRIST ROTATION AND CONTROL THE CONVEYOR BELT. THE ELECTRONIC CONTROL CAN BE USED TO PROGRAM THE ROBOT CYCLE, SO THAT, FOR EXAMPLE, PIECES CAN BE DEPOSITED ON THE ASSOCIATED CONVEYOR BELT.